Reynolds designs equipment for the Adhesives, Sealants, Silicones and Caulks, Coatings and Paints,

Cosmetics and Pharmaceuticals, Inks and Pigments, Rubber, Polymers, Resins, and Foams, and Specialty Chemicals processing industries.

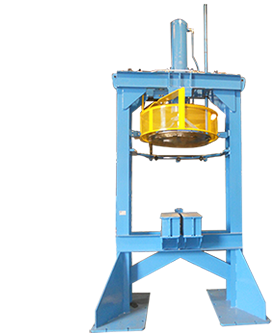

Powerful hydraulic press-out station handles heavy materials with ease when discharging from vessel. Reynolds Industries has built press-out stations for many years. Our units are built in various standard configurations, available with or without lifts. Units are built with the specifications needed to handle your high viscosity or non-flowing products. The Reynolds press-out is built with a rapid advance feature that allows the operator to move the platen at different speeds to minimize wait times during retraction and faster movement of the platen to the product level. In operation, your vessel is positioned and secured on the machines platform. Fixed-height or variable-height platforms are available to suit your application. Use this hard working and durable machine to move your high viscosity or non-flowing products from the final processing vessel to shipping containers, cartridges, or other final packings.

| Vessel size | 100 to 500 Gallons |

| Platen Diameter | 24” to 60” Inch |

| Pressure Rating | 2 to 200 Tons |

| Platen Speed | Plunger speed – up to 2” per minute under load |

| Materials (Wetted Parts) | Carbon Steel, Stainless Steel |

Reynolds Industries can perform lab tests on customer's products. Our process experts will design a mixing system for your new product or to help with your existing mixing process. Our engineering team will determine a cost effective and longlasting systems to meet your processing requirements. Controls can be designed to fit with your existing control systems or new control systems can be designed for ease of operation.