Reynolds designs equipment for the Adhesives, Sealants, Silicones and Caulks, Coatings and Paints,

Cosmetics and Pharmaceuticals, Inks and Pigments, Rubber, Polymers, Resins, and Foams, and Specialty Chemicals processing industries.

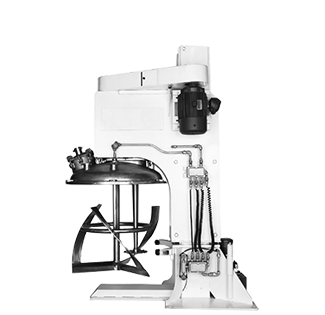

Reynolds Dual Shaft mixer is a powerful, efficient, and versatile mixer that combines a low speed helical blade agitator with a saw-tooth high speed disperser to provide optimum batch turnover in manufacturing of high viscosity products. The helical blade design with a close tolerance gap eliminates hot or cold spots in temperature controlled processes. The helical blade attached with scrapers supports improving heat transfer across jacketed vessel side wall and vessel bottom wall.

Viscous finished product that is too slow to discharge by gravity or/and support with helical blade is usually pressed out of the vessel by a platen-style Reynolds Press-Out Station System which includes a rapid advanced feature with fast and slow platen movement. This technique allows for fast and efficient product discharge transfer with minimal waste and clean-up

| DUAL SHAFT MIXER WITH LIFT | ||||||

|---|---|---|---|---|---|---|

| Model | HP | HS Blade Dia (In) | HS Shaft Max RPM | LS Shaft Max RPM | Standard Lift (In) | Vessel Capacity (Gal) |

| RDSML-2/1 | 2/1 | 2 | 8000 | 50 | 16 | 2-5 |

| RDSML-5/3 | 5/3 | 5 | 4200 | 50 | 24 | 10-30 |

| RDSML-10/5 | 10/5 | 5 | 4200 | 60 | 36 | 30-50 |

| RDSML-15/7.5 | 15/7.5 | 4 | 4770 | 45 | 36 | 30-50 |

| RDSML-25/15 | 25/15 | 8 | 2385 | 45 | 42 | 50-100 |

| RDSML-40/20 | 40/20 | 12 | 1750 | 50 | 46 | 100-200 |

| RDSML-50/25 | 50/25 | 14 | 1365 | 40 | 42 | 200-300 |

| RDSML-75/40 | 75/40 | 14 | 1570 | 40 | 76 | 300-500 |

| RDSML-125/60 | 125/60 | 14 | 1365 | 30 | 60 | 300-500 |

| DUAL SHAFT MIXER WITHOUT LIFT | |||||

|---|---|---|---|---|---|

| Model | HP | HS Blade Dia (In) | HS Shaft Max RPM | LS Shaft Max RPM Range | Vessel Capacity(Gal) |

| RDSM-20/10 | 20/10 | 8 | 2300 | 40 | 100-250 |

| RDSM-25/15 | 25/15 | 8 | 2300 | 40 | 100-250 |

| RDSM-50/25 | 50/25 | 12 | 1200 | 40 | 250-600 |

| RDSM-60/40 | 60/40 | 18 | 1200 | 40 | 600-1000 |

| RDSM-100/50 | 100/50 | 18 | 1200 | 40 | 500-1200 |

| RDSM-150/75 | 150/75 | 22 | 955 | 25 | 1000-2000 |

| RDSM-200/75 | 200/75 | 26 | 770 | 25 | 2000-2500 |

| RDSM-250/125 | 250/125 | 28 | 690 | 20 | 2500-4000 |

| RDSM-300/150 | 300/150 | 30 | 640 | 20 | 5000-7500 |

This is only a sampling of sizes. Many more configurations are available. We can design for any application.

Use press-out system to move high-viscosity or non-flowing products from the final processing vessel to final shipping containers, cartridges or other final packing.

Reynolds Industries can perform lab tests on customer's products. Our process experts will design a mixing system for your new product or to help with your existing mixing process. Our engineering team will determine a cost effective and long-lasting systems to meet your processing requirements. Controls can be designed to fit with your existing control system or new control system can be designed for ease of operation.