Reynolds designs equipment for the Adhesives, Sealants, Silicones and Caulks, Coatings and Paints,

Cosmetics and Pharmaceuticals, Inks and Pigments, Rubber, Polymers, Resins, and Foams, and Specialty Chemicals processing industries.

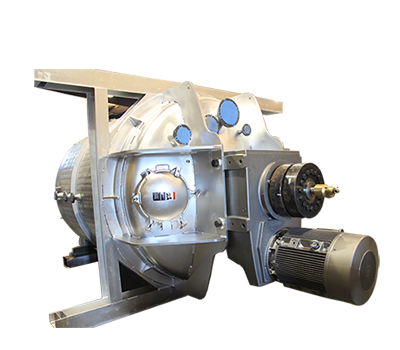

The Low Speed Agitator is designed for processing hard to handle products such as: high viscosity, thixotropic and varying density products. There are several blades designs available but typically recommended is the helical blade design for maximum product turnover. The heat transfer application can be organized into two broad categories. One category is that in which open impellers operate at some distance from the vessel. The second category is a close clearance impeller such as an anchor impeller or helical impeller. Reynolds offer both category mixer with unique features such as the 3-blade patent helical blade with high temperature withstanding scraping technologies. In addition, all Reynolds agitators are supplied with rotating baffles. Reynolds baffle technology helps to break swirling to improve high heat transfer coefficient that allow to reduce horsepower. Rotating baffle integrated with RTD temperature probe that allow fast response on product temperature

| Motor Power | 1 – 125 HP |

| Operating Pressure | Vacuum - 150 psi |

| Impeller-Systems | Reynolds Helical Blade, (Other Impellers: Bar Turbine, Axial Flow Turbine, SpiralBackswept Turbine, Flat Blade Turbine) |

| Materials (product wetted) | Carbon steel, rust- & acid resistant steel, nickel-base alloy, Duplex- & Super Duplexsteel, titanium & titanium alloys |

Reynolds Agitators are a cost -effective alternative to Sigma Mixers (Or Kneaders) and extruders. Reynolds also supplies different style blades that include Bar Turbine, Axial Flow Turbine, Spiral Backswept Turbine and Flat Blade Turbine. Ask our specialists about available blade styles.

Reynolds Industries can perform lab test on customer's products. Our process experts will design a mixing system for your new product or to help with your existing mixing process. Our engineering team will determine a cost effective and long-lasting system to meet your processing requirements. Controls can be designed to fit with your existing control systems or new control systems can be designed for ease of operation.