Reynolds designs equipment for the Adhesives, Sealants, Silicones and Caulks, Coatings and Paints,

Cosmetics and Pharmaceuticals, Inks and Pigments, Rubber, Polymers, Resins, and Foams, and Specialty Chemicals processing industries.

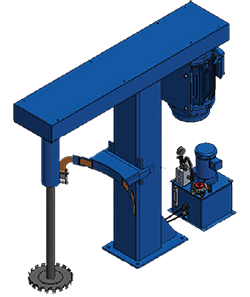

The shear ability of the Reynolds high speed disperser in dissolving powders into liquid base and breaking fragment or lumps of material to form a homogeneous dispersion often reduces traditional mixing batch times. Reynolds was first in introducing large high-powered dispersers with lifting capability and traversing of the mixer throughout the batch that also make it simple to change out batches. The intensity of flow and shear caused by the blade draws powder or solid substance down to the cutting tips of the blade and shaft. Machines can operate in effectively fluid viscosities of water-like to around 50,000 centipoise (cP), whereas viscosities above this usually require dual action or triple action Reynolds dispersers or RHSD with lifting capability. Reynolds disperser is widely used in coating, ink, dye, cosmetic, colorant and pharmaceutical industries.

| Model | HP | Blade Diameter | Shaft RPM | Standers Lift (In) | Vessel DIA Range (In) | Shaft Dia (In) |

|---|---|---|---|---|---|---|

| RHSD-5 | 5 | 6 | 3350 | 48 | 20-24 | 1.5 |

| RHSD-7.5 | 7.5 | 8 | 2550 | 48 | 24-28 | 1.5 |

| RHSD-10 | 10 | 10 | 2050 | 48 | 28-34 | 2 |

| RHSD-15 | 15 | 12 | 1650 | 48 | 32-38 | 2 |

| RHSD-20 | 20 | 14 | 1450 | 52 | 38-42 | 2.5 |

| RHSD-25 | 25 | 14 | 1450 | 52 | 38-46 | 2.5 |

| RHSD-30 | 30 | 16 | 1250 | 52 | 44-50 | 3 |

| RHSD-40 | 40 | 16 | 1250 | 56 | 44-52 | 3 |

| RHSD-50 | 50 | 18 | 1150 | 56 | 50-58 | 3.5 |

| RHSD-60 | 60 | 18 | 1150 | 66 | 50-58 | 3.5 |

| RHSD-75 | 75 | 20 | 1050 | 66 | 56-64 | 4 |

| RHSD-100 | 100 | 22 | 950 | 66 | 62-70 | 4 |

Reynolds Industries can perform lab tests on customer's products. Our process experts will design a mixing system for your new product or to help with your existing mixing process. Our engineering team will determine a cost effective and long-lasting system to meet your processing requirements. Controls can be designed to fit with your existing control systems or new control systems can be designed for ease of operation.